Single Layer Board 94v0 LED Round PCB

Product Description

Keywords:LED Single PCB Board, Fabrication of Single Sided PCB, Cheap Single Sided PCB

JingHongYi PCB,High quality and cheapest Single Layer PCB supplier and manufacturer. We has many years experience in fabricating single layer LED PCB, aluminum PCB and PCB Assembly. With our advanced engineering & production team and high-end manufacturing equipment,ensures perfect insulation between each layer and good performance of every conductor in multilayer PCBs.

(Bar, Round, Number, Letter, Irregular, etc) ALL Shape / Size / Color / Thickness could be Customize upon request. In addition, we can provide SMD processing services.

PCB sample, low volume PCB, mass production PCB are accepttable.

Single Layer LED PCB, Aluminum PCB Advantage

- High thermal conductivity

- Excellent flame retardant

- High mechanical strength

- Very good heat sink

- Dimensional stability

- Electromagnetic shielding,etc.

The single-sided aluminum base PCB board is divided into three layers: aluminum, an insulating layer, and copper. Aluminum is the role of heat dissipation, the insulating layer is the role of heat conduction, and copper is the role of conductivity.

Only one side of the single-sided aluminum substrate PCB has circuit printed on it, and the other side is a smooth wireless path. At present, the most aluminum substrates in the market are single-sided aluminum substrates PCB, such as street lamp aluminum substrates PCB, fluorescent lamp aluminum substrates PCB, spotlight aluminum substrates PCB, high-power aluminum substrates PCB, etc.

At present, there are two kinds of raw materials for single-sided aluminum substrate PCB, domestic and imported. In Shenzhen and Zhongshan, China, there are the most manufacturers of single-sided aluminum substrate PCB. The single-sided aluminum base plate replaces the former FR4 and PCB fiberglass board, with high strength, good heat dissipation, not easy to break and good flexibility.

The thickness of single-sided aluminum substrate PCB is 1.0mm, 1.2mm, 1.5mm, 1.6mm, 2.0mm, 3.0mm, 5.0mm, etc.

Jinghongyi PCB is one of the many PCB manufacturers and suppliers in China, especially good at the manufacturing and fabrication of single-sided printed circuit board(have a hole or no hole), double-sided PCB and Multilayer PCB. The company has been engaged in PCB manufacturing for nearly 10 years, and has rich experience in the production of single-sided PCB and double-sided PCB. Due to the continuous expansion of electronic product market, PCB application market has also been vigorously developed. So single and double sided PCB is also one of the most common PCB types we see. As a result, we produce the most single-sided and double-sided PCBs, so we constantly improve the manufacturing process and do everything possible to reduce costs for customers. Therefore, our single-sided PCB price is also the lowest. Our advantage is not only reflected in the price advantage, but also we can provide you with the production of PCB prototypes, small and medium-sized batches and PCB assembly services.

Our aim is to provide customers with the best cost-effective products and services. At the lowest cost, we also guarantee the best quality of your products. Therefore, we choose FR4, phenolic paper base plate, CEM-1 and CEM-3 composite copper clad plate and other materials, mainly according to the needs of customers or to specify which materials to use.

In addition, our experienced engineers can provide you with product manufacturability inspection and PCB design assistance. You just need to provide your Gerber files.

Single Sided PCB Definition

Single Sided PCBs, also called Single Layer PCB, contain only one layer of conductive material and are best suited for low density designs. Single sided PCB'S have been around since the late 1950s and still dominate the world market in sheer piece volume. Single-sided printed circuit boards are easily designed and quickly manufactured. They serve as the most cost effective platform in the industry.

There are many similarities and differences between single sided PCB and double sided PCB, and we will also explain them here.

Single Sided PCB Manufacture

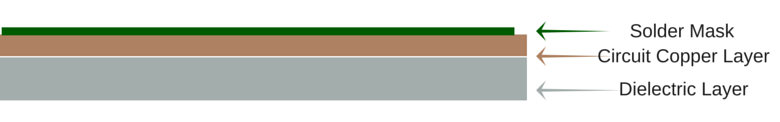

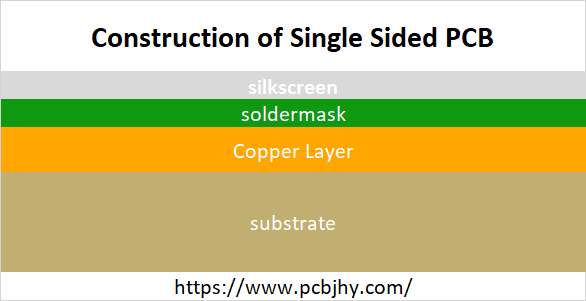

One thin layer of thermally conductive but electrically insulating dielectric is laminated with copper. Soldermask is usually applied on top of the copper.

JHY PCB produces prototype, midrange and high volume Single Sided circuit boards, with a copper thickness from 1 to 20 ounces. Operating temperatures range from 130 C to 230 C. Single sided boards are available with surface finishes including Organic Surface Protectant (OSP), Immersion Silver, Tin, and Gold plating along with both leaded or lead-free Hot Air Solder Level (HASL).

Construction of Single Sided PCB

Above substrate, there lies a copper layer which provides conducting path for various components on the board. The copper thickness is different for different boards depending on your needs and requirements and is defined in ounces per square foot.

On the top of copper foil, there exists a solder mask layer. This layer is mainly used for protection and makes the copper foil insulating which helps in avoiding the conduction in case direct contact happens with some conducting material.

On the top of all layers, there exists a silkscreen layer that is mainly used for adding symbols and characters on the board so a common person can anticipate the clear understanding of the board.

Advantages of Single Layer PCB

- Ideal for simple low-density designs

- Lower cost, especially for high volume orders

- Lower probability of manufacturing issues

- Popular, common, and easily understood by most PCB manufacturers

Application of Single Sided PCB

Aluminum PCB, LED PCB used in LED lighting industry are basically Single Sided PCB.

ALTHOUGH SINGLE SIDED PCBS ARE RELATIVELY SIMPLE, THEY CAN STILL BE USED IN VERY COMPLEX DEVICES:

- Power supplies

- Relays (automotive and industrial)

- Timing circuits

- Sensor products

- LED lighting

- Radio and stereo equipment

- Packaging equipment

- Surveillance

- Calculators

- Printers

- Coffee makers

- Vending machines

- Solid state drives

- Camera systems

Single Sided PCB or Double Sided PCB?

PCBs are more suitable for project design as compared to double sided PCBs and vice versa.

Before you pick any type of PCB for your project, you must take one thing into consideration that single sided PCB layouts are more difficult to route as compared to double sided PCB, but following are the reasons why you should put an effort for making and picking single sided PCB over other PCBs.

- If you are hobbyist or students, and concerned to make PCB at home, you must know, developing single sided PCBs at home are much easier than developing double sided PCBs at home.

- As you are a manufacturer and very much interested to keep your cost down and producing a single sided PCB a most economical process. In terms of cost, producing single sided PCBs are more economical than producing double sided PCBs.

- Almost all HVAC systems make use of single sided PCBs, because they are more reliable and cost effective and don`t compromise the overall quality of the product.

- Using through hole technology in single sided PCBs still have its drawbacks and limitations because conductive layers, lines and pads stay on single side of PCB but it still is a cheap process to combine all components at one place. Multilayer PCB is also used in many applications where single sided and double sided PCBs fail to fulfill the requirements.

Helpful Resources

Introduction About Single-sided and Double-sided SMT Assembly

Single Sided Flexible PCB with Dual Access

Single Sided Flexible PCB

Single Layer LED PCB Round Bulb

Single Layer Metal Core PCB

1 Layer LED PCB

1 Layer Copper Base Board

Product Categories : Single Sided PCB